SMART AND FROM THE HEART

HUGHES & KETTNER SOCIAL WALL

Here are some sneak previews from our social media channels.

Please follow if you like!

Mike Scott - Guitarist for Prince, Justin Timberlake and many others

Hughes & Kettner

November 10, 2023

ERA1 ERA2 great amplifiers for acoustic instruments

Hughes & Kettner

November 11, 2023

GrandMeister Deluxe 40 one of the best guitaramplifiers

Hughes & Kettner

October 19, 2023

Blackspirit 200 - Preset to go!

Hughes & Kettner

September 21, 2023

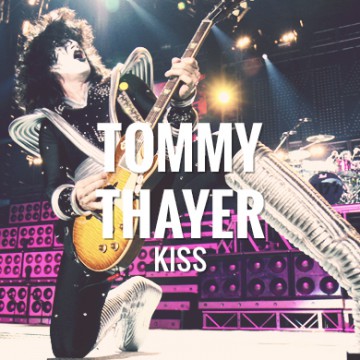

On the couch with Hughes & Kettner

Hughes & Kettner

September 8, 2023

Ambient Guitar with Hughes & Kettner

Hughes & Kettner

August 29, 2023

What is Smart Rotary Control?

Hughes & Kettner

August 22, 2023

Not Only For Guitar

Hughes & Kettner

November 8, 2023